Visit to hackspace with Ben, Alex, Sam, Cameron and Charlie.

Things Done

- Started a 3D print of the nose cone for November Rocket.

- Printed a quarter piece of the gen des skeleton airframe to body tube component designed by Sam.

- Collected Easy Composites order and foam.

- Spoke to technicians about tool pathing for routing foam molds for panels and nose cones.

- Spoke to IFR students about carbon fibre manufacturing.

- CNC routed convex body panel mold.

Conversation with Technician

- Helped with toolpathing

- Said our foam was too low density to lay up CFRP onto.

- Suggested either buying denser foam/modelling board or applying a form of sealant (can't remember name suggested).

- The edges of the nose cone mold were too steep to route using their drill bits.

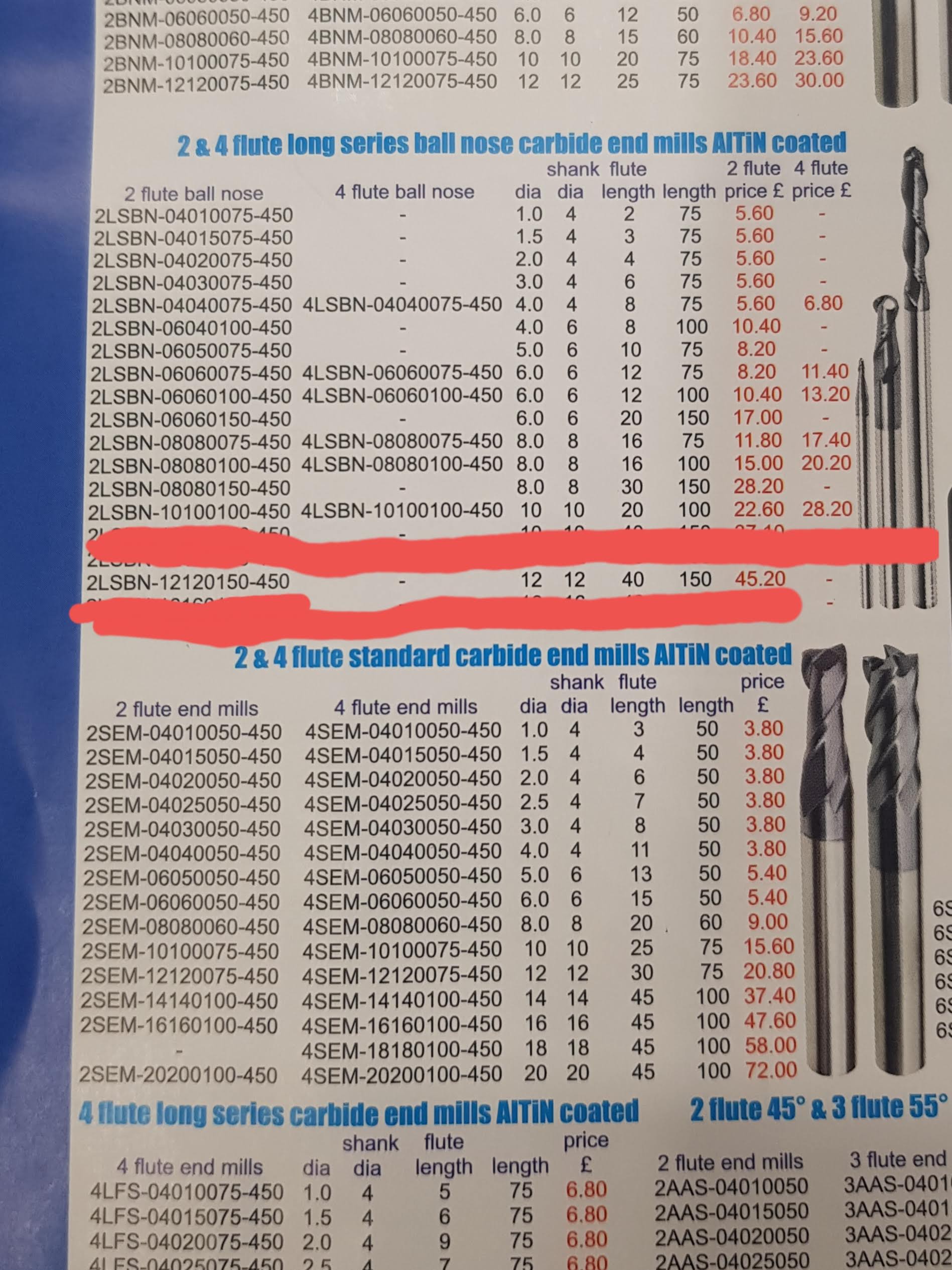

- Suggested buying a new drill bit (see image below):

- Potential alternative discussed between Ben and Charlie was to cut mold up into more manufacturable sections and glue together.

Conversation with IFR

- They have been experimenting with carbon fibre wet layups for several weeks now.

- Have been using large 3D printed molds.

-

The following process should also work for foam:

- One printed, the molds are sanded down to a smooth finish.

- The XCR epoxy coating is applied (see image below):

-

- Allow XCR coating to set overnight.

- Sand down to a smooth finish.

- Apply release wax

- Once wax is semi-set apply epoxy layer (not XCR! The epoxy used for wet layup should be used instead)

- Immediately start layering on carbon fibre and epoxy layers.

- Vacuum bag and leave to set.

- Sand and polish surface.