¶ Electronic Pressure Regulator

Technical Lead : Jack

Priority : Critical

The e-reg is meant to hold pressure in a tank at a setpoint by adjusting the flowrate through the e-reg valve.

Last year had 1 total that controlled both fuel and ox through controlling the pressurant line.

PT that fed into controls system was just looking at fuel tank pressure.

Things that influence the setpoint (where we chose it to be)

- isp through higher pressures into engine

- ideally highest pressure possible but limited by tank max pressures (trade off of tank mass and pressure)

Physics that influences downstream pressure:

- basically just the pressures upstream in the pipe and flow rate through the valve

The rocket engine can have heigher efficiencies if we can get the pipe pressure controlled.

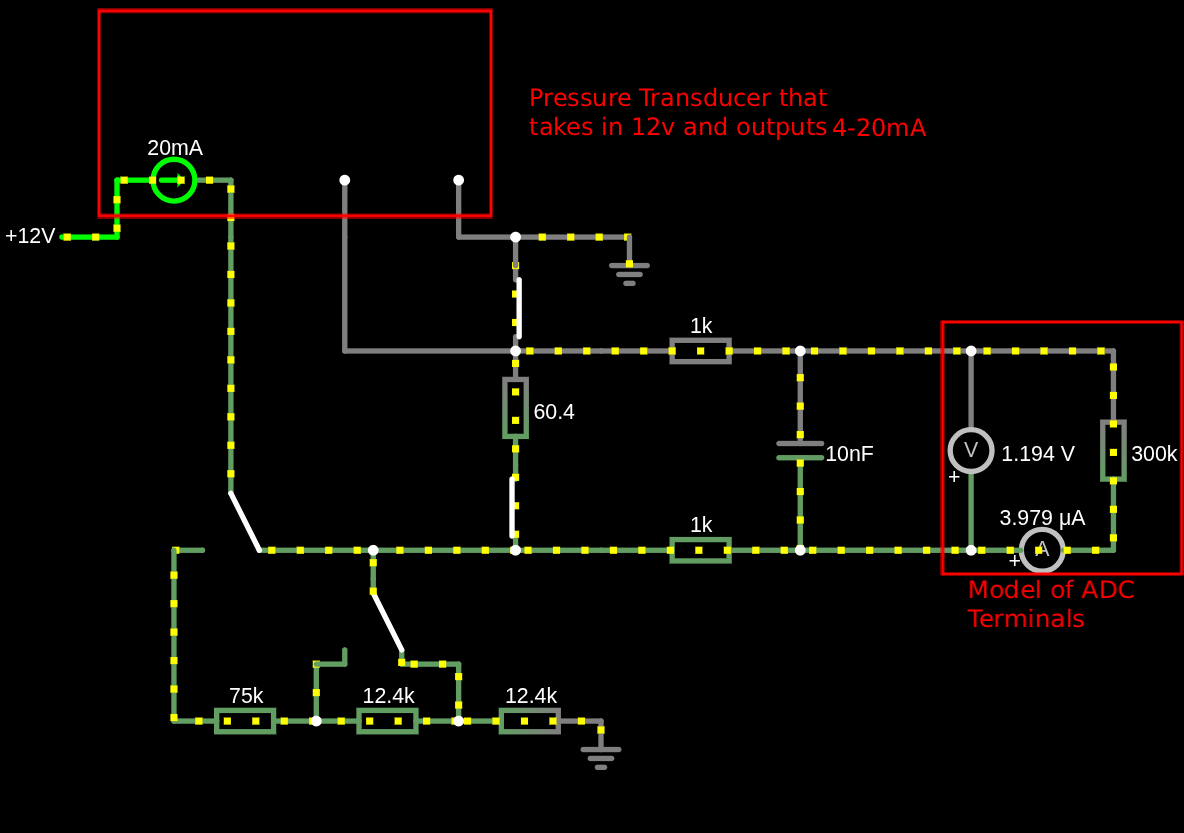

Each board needs to control 1 servo and have 3 pt sensor ports and 2 tc ports.

¶ Tasks

- Schematic completion.

pick whether we hardcode the sensor setup or leave it variable. - PCB Layout.

- Raghav to delegate simulink model creation physics model of propulsion.

- Writing Board Firmware

- Testing and Validation of EReg

¶ Resources

¶ Notes

(9/11/2025) trade-offs are:

more PTs less ideal for prop (harder to integrate + cost)

ideal to have 2 e-reg valves

with each valve seeing pressure before valve, pressure after valve and temperature, one additional pt channel would be ideal

to figure out: how were getting pressure readings from the pressurant tank (ideally not 2 pts but cant split the sensor info)

need to select a new tvs diode part